|

IPST/AFPA |

MODEL 1032 BLACK MAMBA® WEB PRESS

SPLICE DETECTOR™ & DISTRIBUTION TECHNOLOGY |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

If you are a current user of our splice detection solutions, whether you purchased directly with us or by way of OEM (i.e., sheeters, slitters, winders, etc.) you are eligible for preferred pricing on additional units. (Please note the serial number of the unit or units

you have if

purchased via OEM). "Where the Science of Quality Assurance is still an Art!" |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The Model 1032BM Black Mamba™ Web Press Splice Detection & Distribution Technology is to detect the presence of all splices in the web of paper being processed on a high speed web press and generate output signals to notify the press print stations that a splice has been detected. The spacing tolerance between the press print heads or station is very close and there is potential to damage the print heads/station by passing a splice through the press when the press is in ready position. Detection of a splice in the web is critical to allow the system sufficient time to protect the print heads/station.

In general, the Model 1088BM Black Mamba® will:

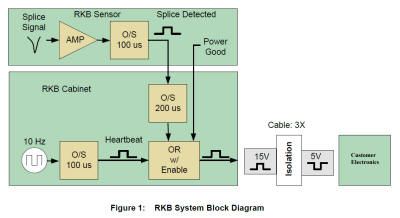

The RKB solution is comprised of two distinct devices including a modified Model 1032B® Classic™ Splice Detector with a physical separate control & distribution cabinet. The sensor unit detects splices and outputs a pulse to indicate the defect "fault" event. The pulse is input to the Black Mamba control & distribution cabinet which combines incoming splice fault signals with a periodic time based signal ("heartbeat") and control processing circuitry. The resulting signal is output via a set of cabling and isolation circuitry to the web press electronics. The processing circuits in the Black Mamba control & distribution cabinet disables the heartbeat output if the sensor unit is not "powered on" or the splice fault signal is not connected. In addition, an option to disable the "heartbeat" independently for each output channel at field installation time is supported. In the latter case, splice fault events detected by the properly connected, powered on, and functioning sensor unit will exit each channel with or without the "heartbeat" depending on the installation specific settings.

Expect Reliability: With installations in over 130 countries worldwide, our splice detection technologies have been effectively established to ensure delivered product superiority on tens of thousands of materials, coated and non-coated such as papers, films, nonwovens, textiles, and tapes. Our splice detection technologies are installed on many types of machinery including sheeters, on and off machine coaters, extrusion laminators, supercalenders, rotogravure and flexographic printing presses, holographic processes, textile and nonwoven machinery. Low speed to high speed, RKB Splice Detectors are proven time and time again to be the leader in performance, reliability and price.

Benefits: Each Black Mamba system installed provides the end users, as well as the web press manufacturer the following:

CONTACT R.K.B. TODAY: Call us today @ 1-315-455-6636 to discuss your complete machine vision imaging application and to learn more about the industry's most diverse line of machine vision web inspection, hole detection, splice detection and control products.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

History | Products | Download Center | News | Refurbish Equipment | Contact | Feedback | Jobs | Industry Links | Search |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Information provided herein protected - © Copyright 2007-2019 R.K.B. OPTO-ELECTRONICS, INC. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Prevent Costly Repair:

Prevent Costly Repair: RKB Technology:

RKB Technology: