|

IPST/AFPA |

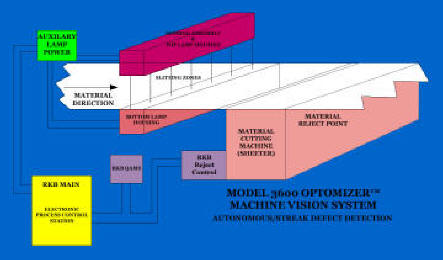

MODEL 3600 OPTOMIZER® FCS SHEETER

INSPECTION™ TECHNOLOGY |

|||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||

|

In today's highly competitive market place, increasing customer demands require comprehensive quality management and control. Sheet fed printing and packaging processes requires a higher end product of specialty coated and non-coated material that is demanding in terms of quality and delivery. Production efficiency standards that facilitate continuous quality control initiatives and machine runnability are essential key components to ensure a competitive edge in this very demanding segment of the market.

The RKB FCS-WIS technology will provide comprehensive quality management to ensure defective material is detected and classified diverting one or any number of successive defective sheets prior to stacking. RKB QAMS (Quality Assurance Management System) Toolpack™ will ensure the most important defects are data mined without time-intensive manual verification processes. Flexible process control initiatives and production recipes allow operational staff to easily setup from run to run quickly and efficiently to ensure all future slit and cut references facilitate the rejection of defective material allowing continuous flow of good material to the stacker.

This technology is the most

advanced state-of-the-art tool utilizing advanced sensor technology

developed by RKB to date and will give your production the ability to

meet quality initiatives instituted locally or through customer

requirements. Production will be maintained efficiently, quality will

increase, customer satisfaction and loyalty will increase providing a

higher competitive positron and higher profits. Detect and Index All Defects: Since most defects require various lighting and detection methods, RKB realized that single source sensing and lighting technologies would not work well and could not meet quality initiatives of a majority of web manufactures, especially in the coated material segment of the market. Dual sensing with flexible lighting techniques developed by RKB, provides the capabilities to detect and index all defects common in any web material manufacturing process.

Using high speed digital linear and patented streak sensor technologies, RKB defect imaging capabilities are much clearer, more accurate and consistent which is unachievable with single source line scan, laser, phototransistor and matrix/video based technologies alone. This blend of both sensing technologies, patented defect signal and noise reduction processes, and our built in data mining catalogue provides precise and comprehensive web quality assessment and unprecedented performance.

100% Inspection Coverage: Each machine vision imaging solution is designed to span the entire web width for 100 percent inspection of the web material. Now you can guarantee that your products are fully qualified prior to subsequent processing or shipment to customers. Our (QAMS) Quality Assurance Management System Toolpack™ is included with each system to provide complete defect data collection, analysis, reporting, setup, and diagnostic capabilities.

Contact R.K.B. Today: Call us today @ 1-315-455-6636 to discuss your complete machine vision imaging application and to learn more about the industry's most diverse line of machine vision web inspection, hole detection, splice detection and control products.

|

||||||||||||||||||||||||||||||||||

|

History | Products | Download Center | News | Refurbish Equipment | Contact | Feedback | Jobs | Industry Links | Search |

||||||||||||||||||||||||||||||||||

|

Information provided herein protected - © Copyright 2007-2019 R.K.B. OPTO-ELECTRONICS, INC. |

||||||||||||||||||||||||||||||||||

Maximize Profitability:

Maximize Profitability: The inspection technology is

mounted prior to the cutter in-feed. Upon detection of a mission

critical defect, a reject gate will be activated momentarily altering

the flow of the "BAD" sheets to a reject bin collection system for

further customer analysis. This ensures the skids of sheeted stock with

value critical defects get stopped at the source before they are

delivered to the customer. These quality initiatives will prevent and

reduce smash blankets, press downtime, damage sensitive components or

coating equipment and delivery delays costing you customers and market

position.

The inspection technology is

mounted prior to the cutter in-feed. Upon detection of a mission

critical defect, a reject gate will be activated momentarily altering

the flow of the "BAD" sheets to a reject bin collection system for

further customer analysis. This ensures the skids of sheeted stock with

value critical defects get stopped at the source before they are

delivered to the customer. These quality initiatives will prevent and

reduce smash blankets, press downtime, damage sensitive components or

coating equipment and delivery delays costing you customers and market

position.