|

IPST/AFPA |

MODEL 3030 OPTOMIZER® MACHINE VISION

WEB INSPECTION TECHNOLOGY |

||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||

|

Undetected defects often result in excessive costs for customer returns, repairs to sensitive production equipment, and machine downtime in today’s high speed web manufacturing operations. The Model 3030 OPTOMIZER® Machine Vision technology provides real time detection and categorization of holes, spots, dirt, coating streaks, and many other types of defects.

The Model 3030 OPTOMIZER® can be integrated with new or existing web manufacturing equipment. These systems can help maximize the profitability of your web manufacturing operations by providing production, maintenance, and setup personnel with immediate notification of defects and the information they need to quickly locate and correct defect producing conditions

Detect and Categorize All Defects:

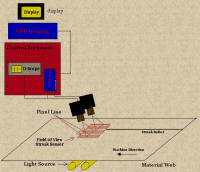

The Model 3030 OPTOMIZER®

use an array of high speed CCD Line Scan cameras for detection of random

defects such as holes, spots, and edge cracks. A separate array of high

resolution Streak Scan sensors is used to provide coating streak and

scratch detection capabilities that are unachievable with line scan

cameras alone. This combination of both types of cameras with

proprietary and patented RKB signal processing technologies provide

unprecedented performance in a single web inspection system.

Positively Mark Edge Defects: Our Model 1280 Guardian® Multicolor Edge Marking™ Technology can be combined with the Model 3040 OPTOMIZER® Machine Vision technology to provide visible edge marks that positively identify the locations of edge cracks within each roll. These marks can then be detected by our Model 1290 AutoDetect® Control System™ that will monitor rolls on subsequent processing equipment for the edge marks and initiate a "STOP" signal to facilitate removal of the defect by operational staff by cutting it out, patching or splicing. The Model 1290 can be installed on any process such as:

These marks can also be detected visually as concentric circles on the outside edge of the roll for manual sorting or grading operations.

Coating defects such as skips, voids and streaks & scratches often result in excessive production costs in today's high-speed coating processes. Our The Model 3030 OPTOMIZER® provide production, maintenance, and managerial personnel with immediate notification of defect events, size, type (i.e., streak or scratch), location and probable cause. Information can then be utilized to quickly locate the defect and take corrective action to eliminate the fault from continuing. Our defect fault imaging technology will help to significantly reduce your company's costs for producing, sorting, and disposing of substandard coated products. Our systems can also help to reduce costs for customer returns, repairs to sensitive production equipment, and machine downtime.

Contact R.K.B. Today: Call us today @ 1-315-455-6636 to discuss your complete machine vision imaging application and to learn more about the industry's most diverse line of machine vision web inspection, hole detection, splice detection and control products.

|

|||||||||||||||||||||||||||||

|

History | Products | Download Center | News | Refurbish Equipment | Contact | Feedback | Jobs | Industry Links | Search |

|||||||||||||||||||||||||||||

|

Information provided herein protected - © Copyright 2007-2019 R.K.B. OPTO-ELECTRONICS, INC. |

|||||||||||||||||||||||||||||

Maximize

Profitability:

Maximize

Profitability:

Process Diverse

Materials:

Process Diverse

Materials: